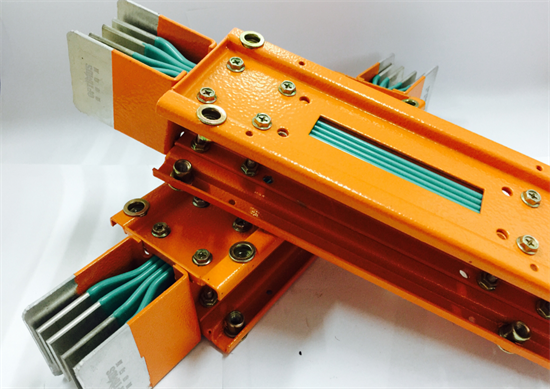

现代高层建筑和大型车间需要巨大的电能,面对这庞大的负荷所需的强大电流必须选用安全可靠的输变电设备,母线槽将是最理想的选择,母线槽的输变电优越性是普通电力电缆无法比较和超越的。母线槽系统是一个高效输变电装置,尤其适应高层建筑物和大规模工厂经济合理配线的需要。

Modern high-rise buildings and large workshops need huge electric energy. In the face of this huge load, the strong current required must select safe and reliable power transmission and transformation equipment. Busduct will be the most ideal choice. The power transmission and transformation advantages of Busduct are incomparable and beyond ordinary power cables. The Busduct system is an efficient power transmission and transformation device, especially suitable for the economic and reasonable wiring needs of high-rise building and large-scale factories.

高层建筑和大型厂房大电流输配电时,若选用电力电缆这需要多增加许多无形的成本,比如车间输配电时每个设备、回路都要重复敷设控制电缆,而且电缆的安全控制起点只能在配电柜内,若发生紧急状况时无法立即切断电源而造成巨大安全风险和财产损失,特别是大型车间工程若使用电力电缆则必须和高强度的桥架、高密度支架及若干固定支架等一起使用,大大增加人工、辅材、机具的经济成本、维护成本,延误工期,降低工作效率。

When using power cables for high current transmission and distribution in high-rise buildings and large factories, there are many intangible costs that need to be added. For example, during workshop transmission and distribution, each equipment and circuit needs to repeatedly lay control cables, and the safety control starting point of the cables can only be inside the distribution switchboard. If an emergency situation occurs and the power cannot be immediately cut off, it will cause huge safety risks and property losses, Especially in large-scale workshop projects, if power cables are used, they must be used together with high-strength bridges, high-density supports, and several fixed supports, greatly increasing the economic and maintenance costs of labor, auxiliary materials, and machinery, delaying the construction period, and reducing work efficiency.

高层建筑和大型厂房使用电力电缆浪费严重,增加故障隐患,比如车间供电需要10000米和母线槽等截面电力电缆时,如果选用封闭母线槽最多只要8000~9000米,因为电缆预算、采购、施工时损耗大,难保管,难库存、难运输,而采用等截面母线槽施工时基本是零损耗,而且母线槽厂家技术人员会积极参与、协助现场,优化现场设计,无偿提供全程技术服务,大大降低用户的使用成本,让用户省事省力省心。

The use of power cables in high-rise buildings and large plants is a serious waste, which increases the hidden trouble. For example, when 10000 meters and Busduct equivalent cross-section power cables are required for power supply in workshops, if the enclosed Busduct is selected, it is only 8000~9000 meters at most. Because of the large loss in cable budget, procurement, and construction, it is difficult to keep, store, and transport the cables, while the construction of Bus duct with equal cross-section is basically zero loss, Moreover, the technicians of the Busduct manufacturer will actively participate in and assist the site, optimize the site design, and provide full technical services free of charge, which will greatly reduce the customer’s use cost and save the time and effort.

从母线槽与电缆性能对比来看,母线槽方案完全优于电缆方案,电缆在施工过程中周期较长,后期维护非常困难,异常情况排查困难,无法得以检测。母线槽的方案,在施工阶段快束,安装简单、安全、可靠。另外可实现温度集中监控,可有效预防设备用电异常。从项目投入资金使用状况来看,铜母线最多,电缆次之,铝母线较低。从母线槽与电缆在投入使用后,电能的损耗曲线来看,电缆运营过程中的电缆损耗幅度最大,而母线槽方案,虽然在项目初期投入稍大,但是在后期运行之后,电缆每年的电损相比母线槽多很多。

From the comparison of Busduct and cable performance, the Busduct scheme is completely superior to the cable scheme. The cable has a long construction period, which is very difficult to maintain in the later stage, and it is difficult to check the abnormal conditions, which cannot be detected. The scheme of Busduct is fast in the construction phase, and the installation is simple, safe and reliable. In addition, centralized temperature monitoring can be achieved, which can effectively prevent abnormal equipment electricity usage. From the perspective of project investment and utilization, copper busduct is the most common, followed by cables, and aluminum busduct is the lowest. From the power loss curve of Busduct and cable after they are put into use, the cable loss is the largest in the cable operation process. Although the Busduct scheme is slightly larger in the initial stage of the project, after the later operation, the annual power loss of cable is much more than that of Busduct.